For a builder

Using Silicate Blocks

Masonry

The same principles apply to silicate block masonry than to the use of other silicate bricks. The base constructions (footing and foundation) must be level, stabile and strong. Proper water insulation must be installed onto the foundation so that the humidity that permeates the foundation would not spread into the walls. The blocks must be moistened before laying and masonry mortar with the right consistency used. In order to create proper adhesion between the mortar and stone, the mortar must not be too dry. In case of a too runny mortar, the mixture will pour out from the joints and the mixture might not achieve the necessary strength. Using a more liquid mixture will not compensate for the need to moisten the stones. The more fine-grained the mixture is, the more convenient it is to work. In hot and dry weather, the wall must be stopped from drying too quickly. Silicate bricks cannot be used for foundations or load-bearing basement walls. Silicate walls must not be covered with something that prevents drying. The wall may be painted with a paint that has a very good water vapour permeability.

Building the wall has to begin from the corner, with a hollow block (in case of a 240 silicate block). It is convenient to place the mixture onto the blocks using a mortar ladle or sled runner as it ensures that the mortar is evenly spread and the joints are even.

A very helpful tool for handling and placing blocks is a jaw. It significantly speeds up work and needs less workers. A dead-blow rubber hammer with lead millet can be helpful in nudging the blocks to the exactly right place.

Use in the partitions of a production building

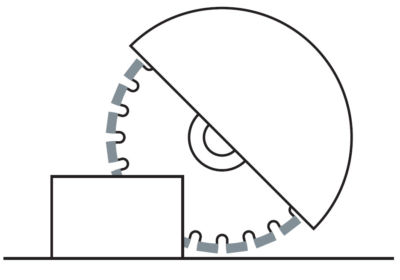

Cutting a silicate block

A suitable tool for cutting blocks and bricks is an electrical disc cutter with carbide teeth. For openings and passages, use a hole saw with carbide teeth.

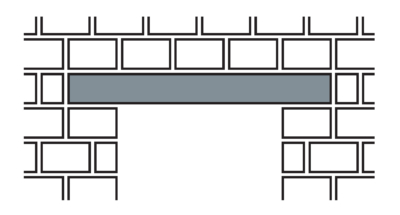

Bridging openings

The weight of the block rows above windows and doors is distributed to both sides of the opening using lintels. Reinforced concrete lintels are most suitable for a silicate block wall. The type of the lintel is determined by the designer. There as to be an uncut block/brick under the footing of the lintel. In case of openings of more than 1.5m, the minimum bearing surface under one end has to be at least 250mm.

Reinforcement

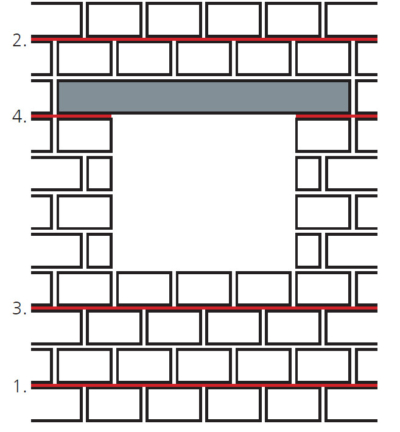

As a rule, a silicate block wall is so strong that it does not need reinforcement. There are still four regions that need constructive reinforcement to prevent cracks.

Be sure to reinforce:

1. On top of the first row of blocks (it prevents tensions spreading from the foundation into the wall)

2. Under the last row of blocks (helps to spread the load of the roof to the wall)

3. Under the row of blocks under openings (spreads the load of window posts to the wall)

4. Under the row of blocks of a lintel (reduces temperature expansion and spreads the load to window posts)

Suitable reinforcements are reinforcement net (in case of mortar) or Murfor EFS reinforcement (in case of using block glue.

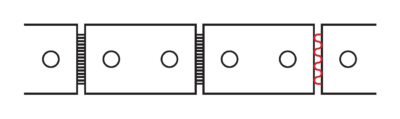

Expansion joints

The purpose of expansion and temperature joints is to prevent cracks caused by reduction of volume in long sections of the wall or changes in temperature. The joints are vertical and pass through the wall. These are filled with an elastic filler, which is why the separated parts of the wall can move in relation to each other without damage. The recommended distance between two expansion joints is 10 m.

Finishing

In case of properly completed masonry, interior finishings can be limited to only complete plastering.

BIM & CAD

BIM and CAD compatible digital catalogue of our products is available from Prodlib:

Download catalogue or use the web version.