PROTECTIVE CAP

The chimney head has to be covered with a concrete cap which protects the chimney head from damage caused by precipitation. The cap has to extend at least 5cm over each side of the chimney to ensure that precipitation is guided away from the sides of the chimney. In the case of tin caps, it is advisable to check the certificates of the product to prevent the caps from rusting too quickly.

FLUE SLEEVE

The purpose of the flue sleeve is to protect the chimney head from damage caused by acidic condensate. Acidic condensate usually results from the low temperature of smoke exhaust – water drops appear on the interior surface of the flue and the floating soot particles dissolve in it. As a protective sleeve you can use both stainless steel and ceramic flue sleeves.

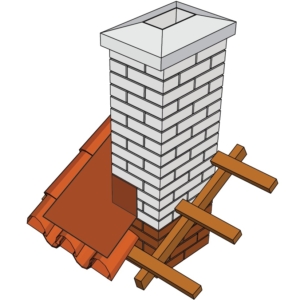

LAYING A CHIMNEY HEAD

Before beginning the construction, it is necessary to soak the silicate bricks in a water tub and then allow them to set in shade. Soaking is necessary to create free moisture in the brick that prevents water being sucked out of the mortar. Otherwise there will not be proper adhesion between the bricks and the mortar and the hair-thin crack caused will collect moisture when freezing and this will break the chimney. Letting the bricks set is necessary to remove the excessive water from the surface of the brick to avoid mortar drooping down the brick. It is recommended to build the chimney head in the spring or early autumn using Silikaat’s cement mortar (T100/300) on a cloudy, humid and calm day. The constructed chimney head must be able to set for a month before the frost season. It is advisable to have the chimney head be built by a worker with a potter’s certificate.

CHIMNEY MAINTENANCE

It is advisable to have your chimney swept twice a year: in the spring after the end of the heating season and in the autumn before the beginning of the new heating season. It is important to remember that the chimney has to be checked by a certified chimney sweep at least once every five years.

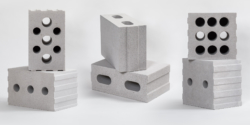

WHY TO USE SILICATE BRICKS FOR A CHIMNEY?

- Natural, environmentally friendly product

- Durable construction material for the Nordic climate

- Weather-proof

- Can survive 108 freeze-melt cycles

- Good properties (smooth surface, precise measurements)

- Traditional Estonian construction material (since 1910)

- Visually attractive

ADVICE FOR STOKING

- The wood used for stoking has to be dried for at least two heating seasons.

- To avoid the creation of soot particles, sufficient ventilation has to be ensured when stoking.

- The fireplace has to have enough space for the flame – a complete full fireplace causes the fire to die out.

- Garbage, including plastic, textiles, painted wood etc. must not be used for stoking.

- Active stoking should last at least 1 hour.