Even though times have changed and in our city space we can clearly see that glass and concrete are the preferred façade materials, Silikaat’s development still has momentum and new innovative products are constantly launched. The reason is that construction blocks are still used for interior walls and houses of up to two storeys, which means that demands on its quality increase every year.

“The development of a company depends on many aspects: on the one hand, the company itself has to have ideas and a desire to satisfy the customer’s needs, but also the vision of the company’s owners is important. Even though it might seem that the field of construction is traditional and set – sand and stone do not change their structure – the wishes and needs of our customers do change. What was fine yesterday, may not be enough today. In case of our products, an example is granular composition,” says the CEO of AS Silikaat, Aare Koll.

“Quality requirements for dry sands and sand mixtures are very high and this is good as a constant challenge is the basis for development.”

Silikaat attempts to foresee the possible trends on the construction market. The main shareholder of the company, Vello Kunman, is a visionary and a person of high standards, who does not stand for complacency. At the mines, there is an activity plan for the next 15 years and investments have been planned for the next five. “As all our departments employ professionally trained and experienced engineers, we feel secure in trusting them and their decisions,” says the CEO.

“Product development must be based on intuition and experiences, followed by a well considered decision. Our field does not develop quickly, there are many restrictions. Every step must be well thought through as there is no point in making pink bricks instead of the traditional white bricks, because – to be honest – nobody needs them!” Koll emphasises.

According to the Strategy Manager of AS Silikaat and Silikaat Group, Anne-Mari Lehtla, development is teamwork. “Someone has an idea, but everyone is involved. The Sales Department tests whether the idea could have a market, engineers make sure that the product can be made with high-quality and the Accounting Department calculates whether the development expenses are reasonable. Everything is synergistic. Consideration and calculation ensures that the product is developed with reasonable prices and the decisions are economically reasonable.”

Upcoming investments for Silikaat will be to update mining equipment, purchasing in the coming years a new sand pump and sand sieve. Also a new dry sand workshop is being designed. As Silikaat’s aim is to make a truly high-quality Estonian product, they use the best practices of the engineers and scientists of Russia, Poland, Germany and Ukraine. “Knowledge is one thing, but the courage to put it into practice is another,” Koll and Lehtla emphasise.

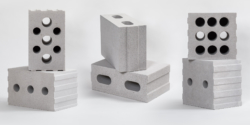

Soundproof wall blocks

As a new product, Silikaat launched the innovative silicate block 120 Slim (measurements 300x120x192), which is mainly designed for building strong and soundproof partitions. The advantage of this silicate block is its economy, expressed by high sound insulation while having compact measurements. This helps the developer gain more surface area for the rooms, whole ensuring a high-quality result for the resident, as light blocks with similar strength and sound insulation and significantly larger, thereby reducing the area of the rooms. Also, silicate blocks not need to be cast full with concrete, nor do their vertical joints need to be filled, which helps to save on working hours and materials.

“We need to stay competitive and continue to update our product selection as do other manufacturers. Silicate blocks have the best sound insulation properties our of all hollow blocks and it is very easy to place cabling into them. Thanks to the density of the material, it is safe to attach heavy objects such as a water boiler or TV-set to the wall. A silicate wall can take anything and has done it for 109 years! Silicate blocks need little reinforcement (only the first row of blocks and lintels), which is a great advantage for a knowlegable consumer as both time and money are saved. The materials used are lime, sand and water, which means that the product is environmentally friendly,” Aare Koll says.

Where are silicate bricks used in today’s world? “Versatile silicate bricks are actively used in both general construction and also the interior and exterior designs of buildings, for example chimney heads, flower boxes and barbeque ovens. We are in close cooperation with the Estonian Chamber of Chimney Sweeps,” the CEO lists. Good examples of the durability of silicate are the building of National Opera Estonia (1910) and the visitors centre at Suur Munamägi (1939) on top of the highest hill in the Baltics.

It might seem that development in such a big company and such traditional field takes a lot of time – larger projects such as planning the sand pumps and a dry sand workshop have taken years – but it is not always so. “Sometimes launching a new product has to be particularly quick in our competitive conditions,” Koll admits and gives as an example a customer for whom construction sand was not suitable for making concrete as it did not have fine sand particles. “So what did we do? In less than a week we developed a new mixture by combining coarse sand with fine sand. The proportions where right, all met the parameters, the customer was satisfied and their market share grew thanks to us.”

Digital age in mining

Similarly to companies of other fields, Silikaat has been affected by the development of information technology. The company’s mines use an interesting software program SeeME, which executes complete analysis of the machine fleet. According to the Strategy Manager, SeeMee enables to operatively analyse the location of the machines, work groups, work intensity and fuel use, enabling to interfere with daily work, plan it from distance and thereby achieve higher efficiency. SeeMe is also important for mining safety.

The article was published in the magazine Inseneeria No. 10(185), October 2018 View the original article.