For a designer

BIM and CAD compatible digital catalogue of our products is available from Prodlib:

Download catalogue or use the web version.

User guide for Prodlib digital catalogue.

Technical specifications

| Block 240 | Block 180 | Block 120 | |

| Measurements (lenght, width, height) | 250 mm, 240 mm, 192 mm | 300 mm, 180 mm, 192 mm | 300 mm, 120 mm, 192 mm |

| Measurement tolerances | T3 | T3 | T3 |

| Compressive strenght (average) for gross surface | ≥ 20 N/mm2 | ≥ 20 N/mm2 | ≥ 20 N/mm2 |

| Normalized compressive strenght | ≥ 20 N/mm2 | ≥ 20 N/mm2 | ≥ 20 N/mm2 |

| Reaction to fire | A 1 | A 1 | A 1 |

| Water absorbtion | < 15 % (per mass) | < 15 % (per mass) | < 15 % (per mass) |

| Water vapor diffusion factor (table value) | 5/10 | 5/10 | 5/10 |

| Gross dry density | 1300 - 1400 kg/m3 | 1300 - 1400 kg/m3 | 1550 - 1650 kg/m3 |

| Equivalent thermal conductivity | 0.56 W/mK | 0.56 W/mK | 0.56 W/mK |

| Frost resistance | F2 | F2 | F2 |

| Fire resistance class | REI240 | REI90 | REI90 |

| Soundproofing | 55 dB | 52 dB | 48 dB |

Reinforcement

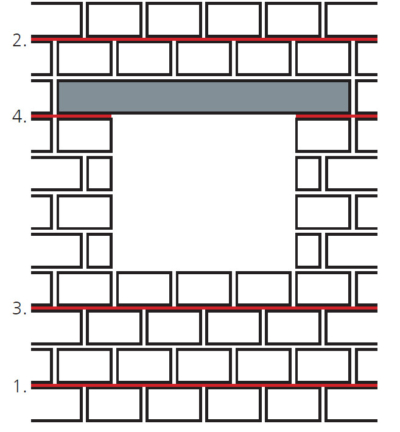

Reinforcing a wall

As a rule, a silicate block wall is so strong that it does not need reinforcement. There are still four regions that need constructive reinforcement to prevent cracks.

Be sure to reinforce:

- On top of the first row of blocks (it prevents tensions spreading from the foundation into the wall)

- Under the last row of blocks (helps to spread the load of the roof to the wall)

- Under the row of blocks under openings (spreads the load of window posts to the wall)

- Under the row of blocks of a lintel (reduces temperature expansion and spreads the load to window posts)

Suitable reinforcements are reinforcement net (in case of mortar) or Murfor EFS reinforcement (in case of using block glue.

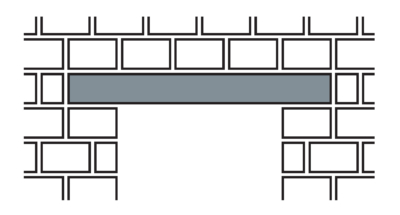

Bridging

The weight of the block rows above windows and doors is distributed to both sides of the opening using lintels. Reinforced concrete lintels are most suitable for a silicate block wall. The type of the lintel is determined by the designer. There as to be an uncut block/brick under the footing of the lintel. In case of openings of more than 1.5m, the minimum bearing surface under one end has to be at least 250mm.

When installing lintels and floor panels, it should be made sure that the lintel or panel would be supported on at least half the block or the instalment should be based on the requirements set in the project. Casting a concrete belt has to be guided by the principles of casting concrete. As silicate blocks have two cavities through it and so it has to be taken into account that concrete will pour into also these cavities and so more concrete will be needed. To reduce the amount of concrete needed, the cavities passing through the block may be filled to a half or three quarters with assembly foam .

In case of silicate blocks, collar dowels can be used to attach scaffolds and fixtures.